Education & Research

Education is not considered a coincidental benefit of the research done at CMST. Rather, educating the academic and wider community about the exciting advances in microplasma is a core component of the mission of the CMST. To this end, a number of innovative programs involving students, in-service and pre-service teachers have been implemented. Also, ongoing efforts are being made to provide resources to science teachers who wish to integrate plasma science into their curriculum using the most current, research based teaching techniques.

Saint Peter’s Prep student Joseph Jordan presents his summer’s work to his colleagues. Joe has spent two summers studying microplasma and gaining valuable experience in the modern instrumentation used in plasma physics.

Under the auspices of the U.S. Air Force and the American Chemical Society, paid internships have been offered to promising high school students from Northern New Jersey. These projects have included learning and teaching about plasma and actual hands-on experience with current research projects at CMST. One example of the work done is a five part video series done by students to introduce plasma science to other students. Other students worked directly with CMST researchers on current projects. Work included UV spectroscopy, analysis of power profiles and analysis of UV production methods.

Research

The current nature of the research spans the spectrum from fundamental inquiries into the basic plasma physics and chemistry of microplasmas to the work on potential microplasma technological applications. CMST maintains five active research laboratories on the Jersey City campus of Saint Peter’s University that support the various research projects. Undergraduate and local high school students have the opportunity to work with CMST staff members on various projects.

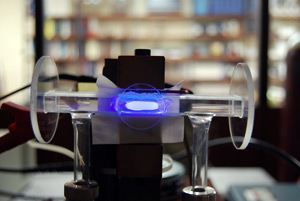

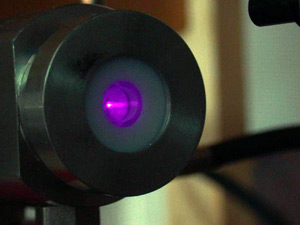

Dielectric Barrier Discharges (DBDs) are usually filamentary in character, consists of a large number of streamers or microdischarges randomly distributed across the dielectric surface. Since DBDs produce normally a filamentary plasma, they do not effectively provide uniform material treatment when used in surface modification applications. However, under special operating conditions (e.g., proper gap distance and sub-microsecond pulsed DC power), DBDs appears to be in a diffuse (glow) mode – as viewed from a magnesium fluoride window in the photo to the left.

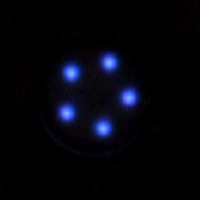

DBDs come in many different arrangements. The one to the right (Cap-DBD) in particular involves metal wires wrapped with capillary tubings and powered by low kilohertz alternating current power. Same and even gap distance maintained all through the device is essential for the successful operation of the device. Cap-DBD is easily expandable to x-, y- and z- directions as well as to cylindrical arrangement, making it a perfect candidate for compact ozone generator, excimer source and volatile organic compound (VOC) remediation.

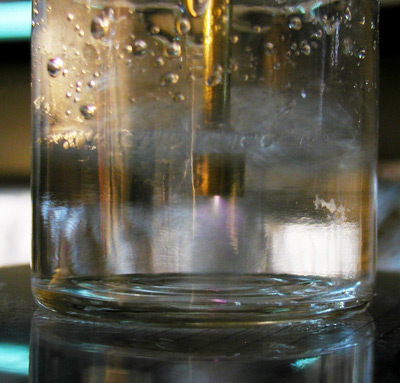

Discharge in water tends to be difficult due to the high dielectric constant of water. Common approaches include high voltage pulsed DC discharge and gliding arc discharge, often with the assistance of noble gas flow through the active discharge zone as well as the addition of electrolyte to alter the conductivity of water. By continuously flowing gas (such as compressed air or noble gas/oxygen gas mixture) through a direct current powered microhollow cathode discharge, a stable plasma microjet (~1-2 cm in length) is generated. Interestingly enough, when submerged in water, a quasi-steady gas cavity forms around the exit nozzle, therefore sustaining the plasma microjet. The plasma generated species interact with water molecule on the gas cavity-water boundary, and particularly on the microdroplets of water that exist within the gas cavity, therefore increasing the efficiency of the plasma-water chemistry. Best of all, the concept has been proven to work in liquids other than water. Potential applications include small volume water disinfection, under-water treatment of skin disorder, dental disinfection and fuel reformation.